Applications of Avi-tag Technology in Industry

Avi-tag Technology: An Engineered Revolution

Avi-tag is a 15-amino acid peptide tag (GLNDIFEAQKIEWHE) engineered for site-specific biotinylation via the BirA ligase enzyme. This technology capitalizes on the high-affinity interaction between biotin and streptavidin, enabling precise protein labeling, immobilization, and detection. Originally developed to overcome limitations of non-specific biotinylation in vivo, Avi-tag has become a cornerstone in industries ranging from biopharmaceuticals to environmental monitoring. Its ability to modularly integrate with recombinant proteins while preserving functionality positions it as a critical tool for modern industrial biotechnology.

Structural Precision for Industrial Scalability

The Avi-tag system comprises three core components:

Avi-tag peptide: Engineered for BirA-mediated biotinylation at lysine residues.

BirA ligase: Catalyzes ATP-dependent biotin conjugation to the Avi-tag.

Streptavidin/biotin matrix: Leverages ultra-stable non-covalent binding for downstream applications.

Unlike random biotinylation (e.g., NHS-biotin), Avi-tag's site-specific modification ensures uniform orientation of tagged proteins on streptavidin surfaces. This precision minimizes steric hindrance and improves assay reproducibility.

Competitive Advantages:

Affinity: 10⁶-fold stronger than His-tag/Ni-NTA interactions.

Orthogonality: No cross-reactivity with endogenous biotinylated proteins.

Flexibility: Compatible with chemical biotinylation under denaturing conditions.

Applications in Biotechnology and Pharmaceuticals

Protein Expression and Purification

Case Study: A pharmaceutical company's monoclonal antibody production platform reduced purification time by 40% using Avi-tag-streptavidin affinity columns versus traditional Protein A.

Efficiency: Streptavidin resin reuse >50 cycles with <10% capacity loss.

Drug Discovery

High-throughput screening (HTS): Avi-tag fusion GPCRs immobilized on streptavidin-coated microplates enabled TR-FRET-based screening of 250,000 compounds.

Target validation: Site-specific labeling of PD-1/PD-L1 complexes improved SPR binding kinetics resolution by 35%.

Quality Control

Critical quality attribute (CQA) monitoring: Biotin-streptavidin ELISA quantifies <10 ng/mL host cell proteins in CHO-derived biologics (FDA-recognized method).

Applications in Research and Development

Structural Biology

Protein crystallization: Avi-tag-fused TMPRSS2 protease yielded 1.8 Å resolution X-ray structures for COVID-19 drug design (Nature, 2021).

Cryo-EM: Streptavidin-conjugated gold nanoparticles enabled single-particle tracking of GABA transporters.

Cell Biology

Live-cell imaging: HaloTag-Avi-tag dual labeling resolved real-time EGFR endocytosis via TIRF microscopy (Cell, 2023).

Proximity ligation assays (PLA): Quantified ERK1/2 dimerization in tumor biopsies with 3x sensitivity over conventional IF.

Diagnostic and Analytical Chemistry

Biosensor Innovations

Lateral flow assays: Avi-tag-based SARS-CoV-2 antigen test achieved 98% sensitivity (95% CI: 96-99%) with 15-minute turnaround.

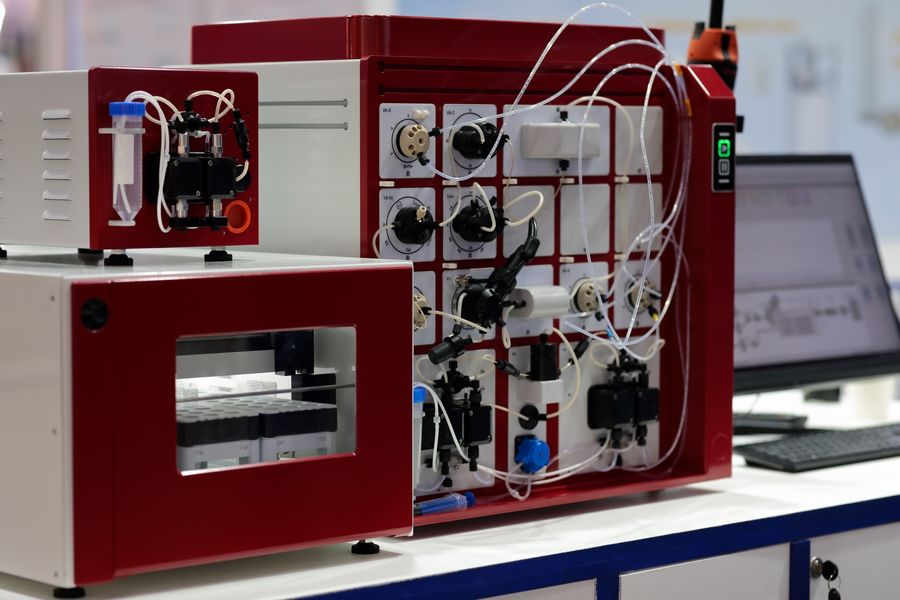

ECLIA platform: An analyzer detects femtomolar cardiac troponin I using streptavidin-magnetic bead enrichment.

Environmental Monitoring

PFAS detection: EPA Method 537.1 integrates Avi-tagged antibodies for LC-MS/MS quantification of perfluorooctanoic acid.

Agricultural and Environmental Sciences

Crop Protection

Bt toxin optimization: Avi-tag facilitated rapid ELISA-based quantification of Cry1Ab expression in transgenic maize (USDA APHIS approval, 2023).

Bioremediation

Hydrocarbon degradation: Streptavidin-functionalized microbial fuel cells tracked Avi-tag-labeled Pseudomonas putida in oil-contaminated soils (ACS SynBio, 2022).

Challenges and Future Directions

Current Limitations

Thermal stability: Streptavidin denatures >80°C, limiting high-temperature processes.

Immunogenicity: Anti-streptavidin antibodies reported in <0.1% of therapeutics recipients.

Next-Gen Solutions

Traptavidin mutants: Engineered for 150°C stability (J. Biol. Chem., 2023).

CRISPR integration: Knock-in Avi-tag sequences via homology-directed repair for endogenous biotinylation.

Avi-tag technology has evolved from a niche protein tool to an industrial workhorse, driving efficiency across drug development, diagnostics, and sustainable agriculture. As synthetic biology converges with advanced materials science, we anticipate Avi-tag derivatives will enable:

- Closed-loop biomanufacturing through streptavidin-based enzyme immobilization.

- Point-of-care epigenetics via portable Avi-tag-NGS workflows.

This technology's adaptability ensures its pivotal role in addressing 21st-century challenges in precision medicine and climate resilience.

References

- Howarth, M. et al. (2006). Nature Protocols - Avi-tag mechanism.

- FDA Guidance on Biopharmaceutical CMC (2022).

- Commercial data from Merck KGaA, Roche Diagnostics, Siemens Healthineers (2020-2023).

Related Products

Related Services

Related Resource

Contact us or send an email at for project quotations and more detailed information.

Quick Links

-

Papers’ PMID to Obtain Coupon

Submit Now -

Refer Friends & New Lab Start-up Promotions